A COVID killing machine is set to reduce infections and save the country millions of pounds at a time of soaring absenteeism and energy bills by purifying the air without letting in the cold.

The new device takes in room air, passing it over germicidal UV-C light which neutralises the threat. The clean air is then pumped back into the room, a process that on average takes just 20 minutes.

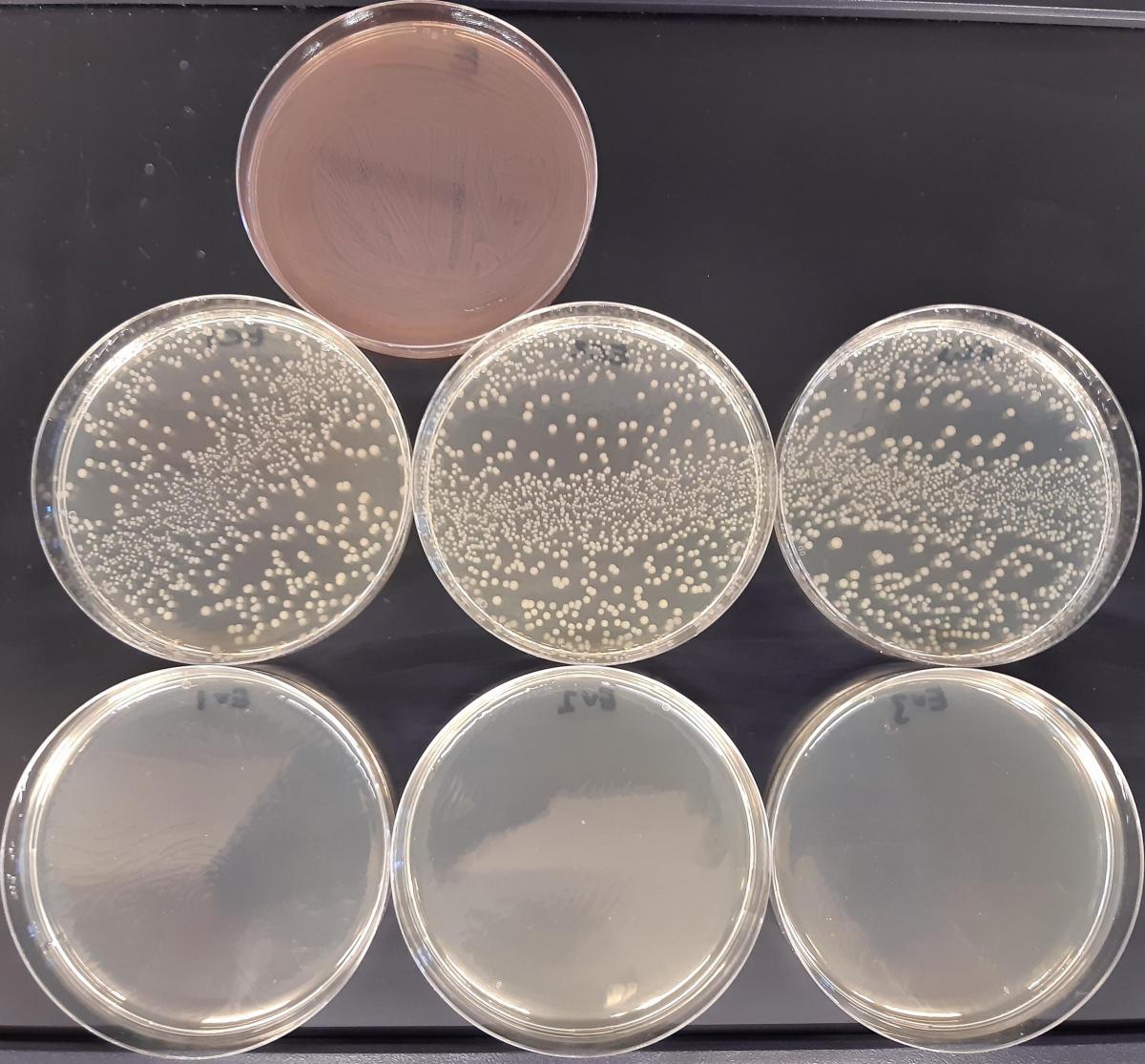

The machines are being trialled in dentists, hospitals and schools around the country. As part of the trials, petri dishes containing agar gel, are being placed in rooms around the respective buildings. These collect and grow a variety of bacteria and viruses that exist in the air which are then compared with dishes placed in rooms containing the sanitiser units.

Engineer Barry Paterson, of Burton Salmon, between Leeds and York, who worked for 20 years in the sustainable energy industry, came across the technology while looking for ways to protect his elderly in-laws from COVID.

“I needed something that would look after my in-laws who are in their 90s,” said Barry, who sits on the Institute of Mechanical Engineering COVID taskforce and is considered a leading expert in UV-C sanitising. “I researched the topic and made a first prototype version myself.”

Barry enjoyed a successful career in biomass powerplants and knew Richard Andrews, CEO of Dudley family owned manufacturer, Midtherm Flue Systems Ltd. He approached Richard about making a UVC sanitiser in the UK during the first week, of the first lockdown. Within a week the new company Midtherm UV Ltd was established.

“It took about 18 months from scratch, half of which we have been in talks with the NHS,” said Barry.

The MT units are simple, reliable and cheap to run. “Just plug-in and play,” said commercial manager John Cooper, also of Burton Salmon. “Lamps last 9,000 hours, which equates to a year if they are on 24/7, starter units last 100,000 hours and the fans are modular and easily replaced.”

They are also more effective than ventilation which blows around the pathogens and leads to greater heating energy costs at a time of spiralling prices and fears for the environment.

Ventilation also fails to eradicate the source of the infection allowing COVID wards to become full of virus, an increased risk to patients and staff.

The technology behind the disinfecting qualities of certain frequencies of UV light date back to 1837. UV-C rays, in the range of 100-280 nanometres, have a strong germicidal effect on bacteria, viruses, spores, fungi, moulds and mites as they destroy their DNA, damage their reproductive system and prevent them from replicating. UV-C is already used widely in food and pharmaceutical industries.

The intensity of the UVC radiation is designed to “kill” a wide range of bacteria and viruses including the Bacillus, Coli, Clostridium, Legionella, Vibrio, Salmonella, Listeria, Pseudomonas, Staphylococcus, Streptococcus, SARS-COV-2 , influenza, measles and respiratory virus.

Because the germs are inactivated there is no need for expensive high-efficiency particulate air filters, which become blocked, impede flow and efficiency and then becomes a bio-hazard needing the expense of clinical disposal.

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules hereLast Updated:

Report this comment Cancel