THEY have been frozen in time – in fact at a random selection of different times – since their power was switched off some years ago.

But now the hands of three large clocks, situated on Nestlé’s factory perimeter in Haxby Road and Wigginton Road, York, have all been turned to just after eight O’ clock – to mark the 50th birthday of After Eight.

A Nestlé spokesman said the clocks had been powered by electricity, but supplies were cut off when production moved from the southern side of the factory to the northern side.

Nigel Anfield, a Nestlé employee whose family members have worked at the factory for more than a century, moved the hands.

“It is a small gesture for the anniversary but something that will act as a reminder for many years,” he said.

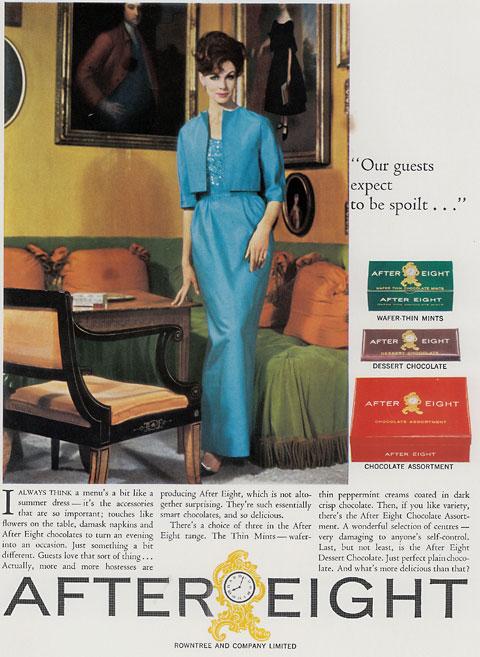

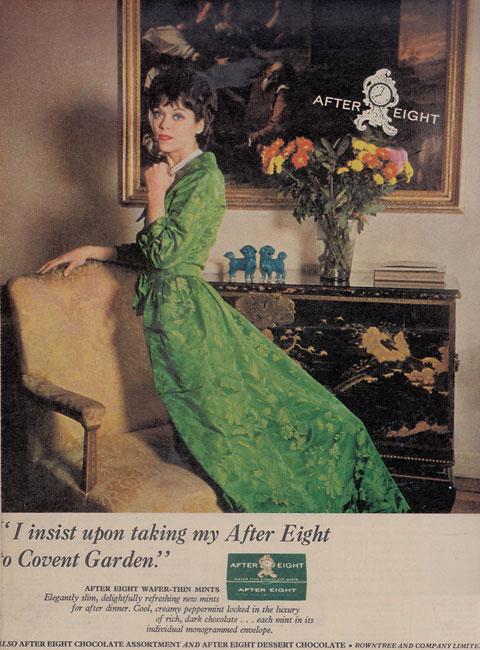

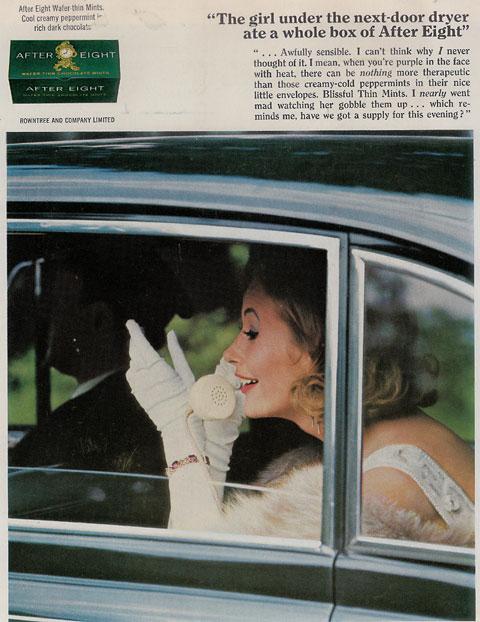

The spokesman said After Eight was conceived in York in 1962 and made in the city until the early 70s. He said the chocolate-covered, wafer thin mint was an overnight sensation, and the York factory went into overdrive to meet demand as the mint became an institution at dinner parties and Christmas tables across the UK.

It was estimated that more than one billion boxes of After Eight had since been sold in the UK but a team at Rowntrees had had to pioneer new ingredients and manufacturing techniques in order to overcome significant challenges in devising After Eight.

The main problem was that traditional fondant would mix and mingle with the chocolate.

“The magic ingredient came in the form of an enzyme which allowed set fondant to be used. Once enrobed in chocolate, the enzyme would soften the fondant – a process which took two-weeks.”

The first ones were made by hand, with the fondant painstakingly piped out and cut into squares once the fondant had cooled and then covered with dark chocolate before a modified hair dryer was used to blow off the excess chocolate and create the signature ripples.

“Over time, a full mechanised production process was introduced and After Eight mints could go into full distribution.”

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules hereLast Updated:

Report this comment Cancel